MESDAN MARTINDALE

Testing procedure

In conformity with the International Standards, the fabric specimen to be tested is brought into contact and rubbed against a Standard reference fabric (as regards abrasion test), or against the same type of specimen, or against a standard felt (as regards Pilling test), following a predetermined number of specific rotary motions known as “Lissajous figure” paths. Basically, the abrasion test end point is reached once the operator visually detects the first two broken threads on the tested fabric specimen, whereas the Pilling test is accomplished by observing (after e certain number of laps), the created pill effect (fuzzing surface / surface disturbance) on the fabric specimen and comparing it with the special photographic standards. For Pilling tests according to EN, ISO, and EMPA (also called “Swiss Pilling”) Standards, a particular sample holder is required (with special dimensions and weight) as well as special photographic standards: EMPA 991 for woven fabrics, and EMPA 992 for knitted fabrics.

ISO 9001 Calibration Report available on request.

ISO 17025 Calibration Certificate (Accredia - ILAC) available on demand.

Instrument for the control of abrasion and pilling on almost any kind of woven and knitted fabrics, non-wovens, socks, gloves, natural and artificial leather, both dry and wet samples.

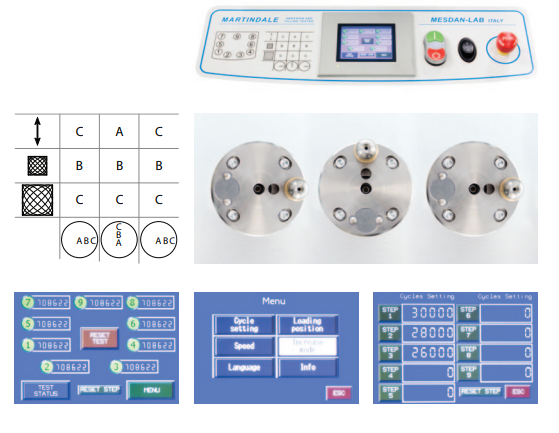

Model with 9 positions with LCD touch screen display, equipped with single and total rotation counter. It isequipped with an intuitive software for the setting of testing parameters.

Three types of test can be performed:

- abrasion,

- pilling,

- straightline motion.

Also a 6-position model, (Code 2568A) is available on request

Technical Features

- Two models available: Martindale 6 positions, Code 2568A; Martindale 9 positions, Code 2568.

- Modular & Flexible: the 6-position model can be further upgraded up to 9 positions by means of specific upgrading kits.

- User-friendly control panel characterised by:

- wide LCD touch screen display for easy setting of testing parameters;

- graphic layout of the testing heads;

- graphic scheme to select the type of test and the movement path;

- start/stop and emergency keys.

Three types of test movement: abrasion (big Lissajous),

pilling (small Lissajous)

rubbing (linear).

The desired movement is performed according to the set position of the 3 driving pivots, as shown by the graphic scheme on the control panel.

Intuitive software for the setting of testing parameters, such as number of cycles per testing step (with consequent stop), speed (23,75 - 47,5 - 71,25 rpm), increase/decrease counting modality, display language, counter providing the total n° of cycles (of all positions) as well as the total n° of cycles of each individual position. The latter is resettable, a convenient function to monitor both the wear of mechanical parts as well as the consumption of consumables on each position separately.

COMPULSORY ACCESSORIES FOR 6-POSITION SETTING (at least one is needed)

Set of 6 sample holders Ø 38 mm for ABRASION test according to UNI EN ISO 12947-1 and PILLING test according to ASTM D4970.

Set of 6 sample holders Ø 90 mm for PILLING test according to UNI EN ISO 12945-2.

COMPULSORY ACCESSORIES FOR 9-POSITION SETTING (at least one is needed)

Set of 9 sample holders Ø 38 mm for ABRASION test according to UNI EN ISO 12947-1 and PILLING test according to ASTM D4970.

Set of 9 sample holders Ø 90 mm for PILLING test according to UNI EN ISO 12945-2.

COMMON SAMPLE CUTTERS FOR 6 & 9 POSITIONS - OPTIONAL

Sample cutter to obtain Ø 140 mm discs for PILLING test Sample cutter to obtain Ø 38 mm discs for ABRASION & PILLING test.

Sample cutter to obtain Ø 90 mm discs for PILLING test, if pre-cut discs are not available.